Introduction

Today, the energy sector is among the key industries that is applying technologies in the digital age to enhance its functionality and dependability. Among these developments, eesy-innovation’s Smart Seal technology can be deemed a revolutionary development in the field of industrial sealing solutions. As a solution to the challenges of monitoring and maintaining such a massive and sometimes distributed pipeline networks, like oil and gas, the eesy-innovation’s Smart Seal incorporates wireless sensor technology and cloud analytics for real-time monitoring and predictive maintenance to ensure pipeline integrity and leak detection.

In this article, we demonstrate the technological parameters of the Smart Seal, best practices, and potential development to explain the contribution of the innovation to the energy sector. In this post, we examine our Smart Seal solution to illustrate how it is revolutionizing maintenance, increasing operational efficiency, and ensuring the reliability of critical transportation pipelines. As the concern for viable and clean energy grows, technologies of this nature are likely to play a significant role in meeting the world’s energy needs.

Summary of Issues Related to Pipeline Maintenance

Challenges of Traditional Pipeline Maintenance Methods:

Having a vast network of pipelines poses numerous challenges which are very vital to meet for enhanced operation and environmental safety. This section explores the core issues related to pipeline management.

Below are some of the major difficulties of keeping extensive pipeline networks:

- Geographical and Environmental Factors Affecting Pipelines:

Pipelines often cross difficult terrains, and face different environmental conditions such as extreme weather, fluctuating temperatures, and natural calamities affecting the pipeline’s integrity.

- Operational Scale and Complexity:

The large size of pipeline networks complicates the maintenance process. Due to the decentralized layout of numerous pump stations, valves, and other important parts, it becomes very difficult to guarantee the proper working of each segment.

- Safety and Environmental Risks in Pipeline Operations:

Over 80% of leakage or isolation issues of pipelines are due to poor installation. Pipeline sealing failures can cause major environmental disasters and pose a threat to life and property.

- Scheduled Pipeline Inspections:

Conventional pipeline maintenance entails the use of inspection-based methods where technicians physically inspect and manually correct any faults at specified intervals. While this ensures periodic reviews, the process is tiresome and time-consuming.

- Transitioning from Reactive to Proactive Pipeline Maintenance:

Maintenance management is frequently done reactively, meaning problems are addressed only when they occur. This leads to a situation where the organization faces the consequences of failure instead of avoiding them in the first place.

- Reducing Manual Data Collection in Pipeline Management:

It is common for technicians to gather information on paper during site visits. This collected information is then used to look for areas of concern. One of the drawbacks of manual data collection is that it is time-consuming, can be inaccurate, and does not always allow for detailed analysis.

Why Innovative IoT Solutions is Required?

Implementing Remote Monitoring for Pipeline Components:

Remote monitoring technologies can overcome the geographical and logistical barriers associated with conventional methods. The use of wireless sensors and real-time data acquisition means pipeline components can be monitored from a central location, minimizing the need for on-site monitoring.

Predictive Maintenance for Oil and Gas Pipelines:

Predictive maintenance identifies conditions that may lead to failure and takes preventive measures before failure happens. Through analysis of patterns in data from the sensors, these systems can determine when and which components are most likely to fail and schedule maintenance accordingly.

Digital Transformation in the Energy Sector:

The use of digital technologies in pipeline maintenance is effective, efficient, and economical. Cloud-based platforms, IoT devices, and advanced analytics tools give a holistic view of the pipeline state, ensuring maintenance work is targeted at problematic areas, increasing reliability and safety levels.

Summing it up, traditional methods of pipeline maintenance, though efficient to some extent, include certain drawbacks that cause inefficiency and higher risk levels. The necessity of innovations like remote monitoring of equipment and predictive maintenance is evident. These technologies not only solve inherent problems but also open up a new horizon of a more reliable and efficient maintenance regime for critical energy infrastructures.

Technological Features of Eesy-innovation Smart Seal

Smart Seal technology is one of the newest industrial sealing solutions provided by eesy-innovation GmbH. This section provides information on the major elements of the Smart Seal technology, how the wireless and battery-operated sensors function, and how data is analyzed and secured using the cloud-based platform.

Key Components of Smart Seal Technology

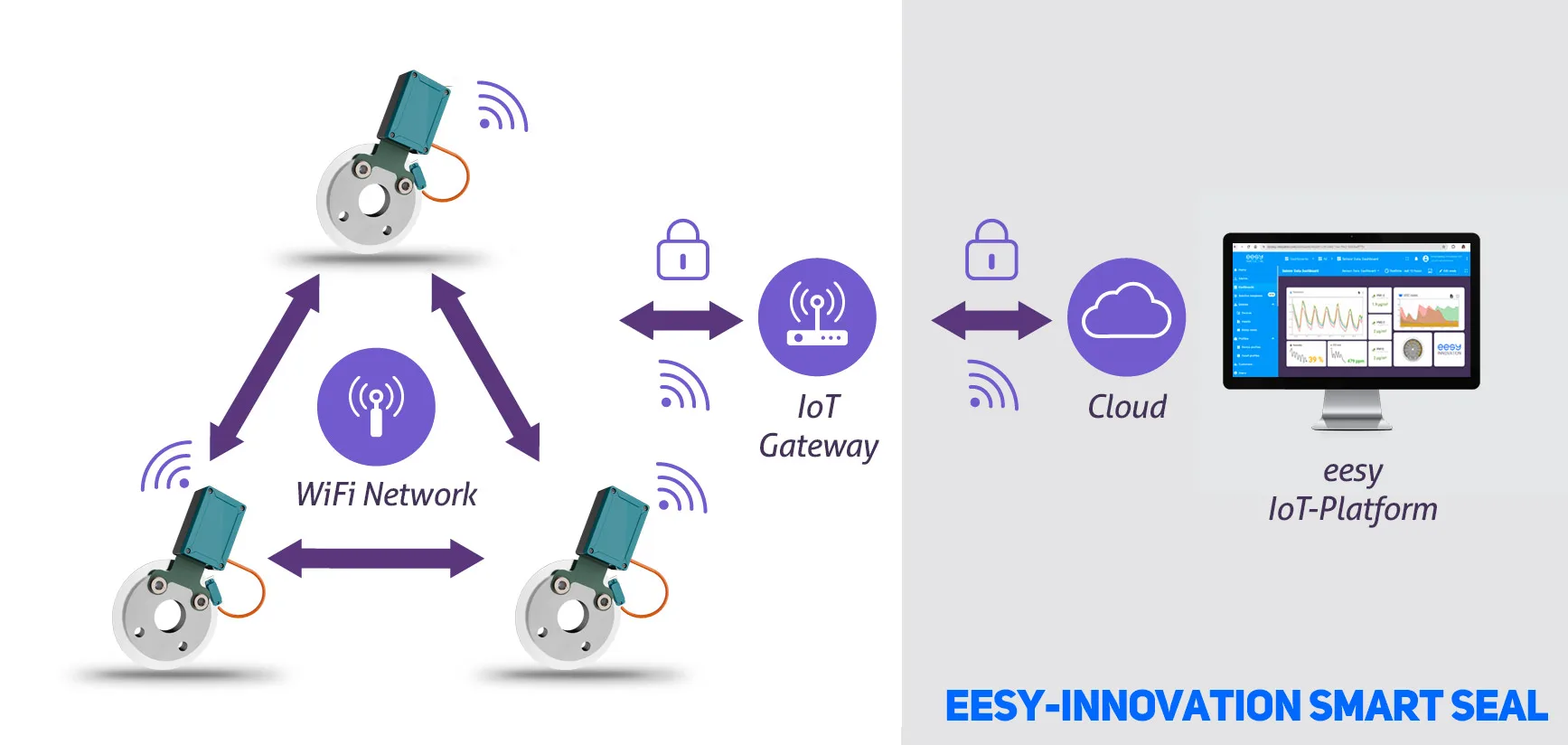

Our Smart Seal technology is built around several key components that work together to provide comprehensive monitoring and predictive maintenance capabilities:

- Wireless, Battery-Powered Sensors: These sensors are incorporated in the mechanical seal employed in pipelines. They constantly check parameters like temperature, pressure, and vibration that are important to equipment.

- Wireless Communication Protocol: This protocol ensures that the data collected by the sensors is transmitted securely and with minimal loss through wireless channels to a central gateway. The protocol also secures data during transmission through encryption and authentication to ensure only permitted devices are connected to the network.

- IoT Gateway: It gathers information from the sensors and then forwards the same to cloud platforms.

- Eesy Cloud Platform: This platform stores and analyzes the data, can run AI algorithms, and provides insights and alerts to operators.

In summary, the technological components of the Smart Seal developed by eesy-innovation are a set of innovative elements and systems that monitor the status of industrial pipelines and predict their failures.

Operational Benefits of Smart Seal Technology

Smart Seal developed by eesy-innovation is very useful for the operation, sealing technology, and management of oil and gas pipelines. This section concludes the advantages of the technology, how it improves performance by providing check and monitoring for upkeep, and the flexibility of not having to visit the site frequently to retrieve information.

The following are some of the benefits of using Smart Seal Technology:

- Proactive Maintenance: The ability to identify areas that may fail in the future allows for early maintenance, hence reducing disruption and increasing the time between maintenance periods.

- Cost Savings: Early indications of problems and the scheduling of preventive measures reduce the number of calls and the time/money spent on them.

- Extended Seal Life: By monitoring the operating conditions, seals and components are well protected, enhancing their useful life.

- Immediate Detection: Real-time data can be used to act immediately on any deviation from the average.

- Informed Decisions: Maintenance schedules and operations can be performed by operators using real-time information.

- Optimized Schedules: Maintenance is done according to the real condition of the equipment, improving the effectiveness of resource usage.

- Increased Flexibility: Operators can make decisions while on the move or from any place with an internet connection.

- Centralized Monitoring: Data obtained from various locations provide a general status of the pipeline.

- Safety Improvements: It is safer to access distant or dangerous areas rarely or after a very long time.

Smart Seal technology enhances reliability, reduces costs, and improves the durability of parts through monitoring and prevention. Availability of information from other centers and less physical attendance also helps in cutting costs, avoiding risks, and establishing business resilience.

Future Developments and Innovations

This section outlines future work on Smart Seal technology with regard to the creation of new algorithms, further analysis of the data, and presenting a new series of seals for increased digital control.

Innovations in Sensor Technology for Extreme Conditions

The following are some future developments and innovations likely to shape the existing structures:

- Improved Sensor Technology: Innovations will focus on increasing sensor precision, reducing power consumption, and ensuring performance in more extreme conditions. This will enhance sensor durability and life expectancy.

- Expanded Sensor Capabilities: Future Smart Seal developments will incorporate more sensors to measure additional characteristics, better describing the state of the seal and pipeline.

- Enhanced Predictive Maintenance: New machine learning models will process historical and real-time data more effectively to discover patterns and predict failures, allowing for even more proactive maintenance scheduling.

- Automated Condition Assessment: Future algorithms will enable automated condition assessment of seals, reducing the time spent on analysis.

Conclusion

Smart Seal technology by eesy-innovation is an innovative product in the energy sector emphasizing effectiveness and dependability. Smart Seal is a wireless sensor system linked to cloud analytics providing real-time monitoring and predictive maintenance for pipeline networks. It eliminates problems such as geographical barriers and traditional maintenance limitations. The Smart Seal brings a new approach to pipeline maintenance, offering benefits like active maintenance, cost-effectiveness, and organizational flexibility. Additionally, the innovation of new sensors and machine learning-based maintenance models reflects the company’s aim of further development. In other words, Smart Seal is the perfect example of how technology can be used to overcome the difficulties of dependability, performance, and reliability of essential energy structures in the contemporary world.

FAQ

What is the role of Smart Seal in pipeline maintenance?

It also makes it possible to perform predictive maintenance where possible faults are determined before they cause failures, minimizing on time losses and other related costs.

What are the important elements of the Smart Seal system?

They consist of wireless battery operated sensors, wireless communication link, IoT gateway, and cloud database for storing and analyzing data.

What issues does Smart Seal solve that other maintenance methods fail to solve?

Smart Seal erases geographic constraints, enhances the quality of data, and changes the approach in maintenance from firefighting to prevention.

What value does Smart Seal bring to the pipeline operations?

Smart Seal advantages include lower costs, longer seal life, quick identification of problems, better scheduling of maintenance, and remote control.